Explosion-proof junction box introduction and application

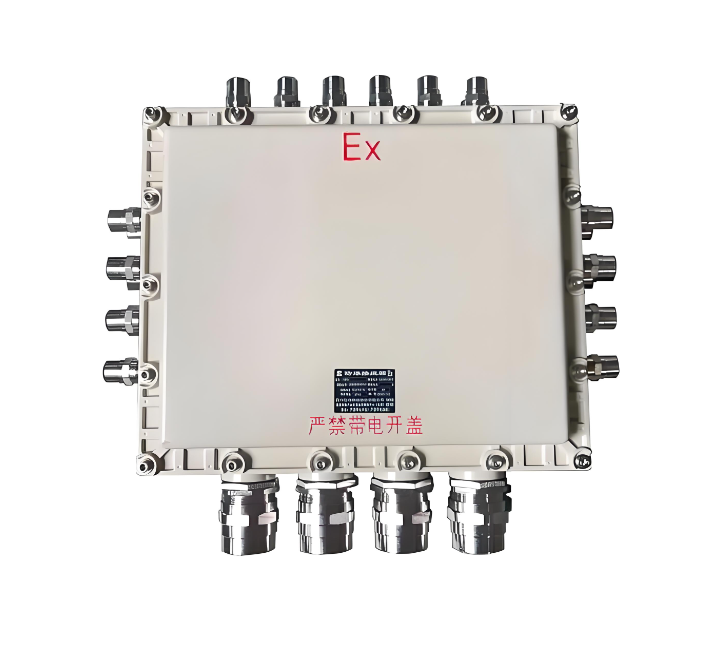

Explosion-proof junction box

In industries such as petroleum, chemical, coal mining and metallurgy, there are often scenarios of combustible gases or dusts in the production chain, which are flammable, explosive and dusty environments. Ordinary electrical equipment in the operation process, if an electric spark, will inevitably cause combustion or explosion, resulting in significant casualties and property damage. How can electrical equipment be used safely in these environments? Explosion-proof products came into being, explosion-proof cabinet is a very important electrical products, which in addition to preventing fire or explosion, but also to prevent dust, moisture, smoke and other pollutants into.

Compared with the civil junction box, the explosion-proof junction box is transformed into a wiring box with explosion-proof function. Electrical equipment in use must be connected by wire or cable and power supply network to form a system to complete the use of its function; but the connection wire or cable can not be infinitely long, and in the connection process there are many places need to be connected in series, parallel for the wire tap. This will inevitably cause the joints partially exposed, easy to cause accidents. Explosion-proof junction box products is to solve these problems and production of products, in order to further ensure safe production.

Common Concepts of Explosion Protection

First of all, we would like to introduce some common concepts about explosion protection:

Different countries and regions have different standards on explosion-proof, the following main reference is to China’s GB standards, the International Electrotechnical Commission’s IEC standards, the European EN standards, the European Union developed the ATEX Directive, NEC505 standards. It should be noted that the North American use of the NEC500 series of standards and the text of the difference is large, if the user needs to meet the NEC500 series of standards, it is necessary to select according to the corresponding information, can not refer to the following.

Classification of explosive substances

Explosive substances are divided into three major categories according to the degree of flammability: 1, underground coal mines due to the presence of gas and coal dust classified as Class I, and will not continue to be subdivided; 2, the rest of the explosive gases are divided into ⅡA, ⅡB, ⅡC three levels; 3, explosive dust can be divided into ⅢA, ⅢB, ⅢC according to its characteristics. mark ⅢB equipment can be applied to the use of ⅢA conditions of the equipment, the sign of ⅢC equipment can be used for ⅢB and ⅢA The equipment labeled ⅢC can be used in the conditions of ⅢB and ⅢA.

Classification of explosive hazardous areas

Zone 0: Continuous or frequent presence of combustible gases, etc. under normal conditions.

Zone 1: Combustible gases, etc. may be present under normal conditions.

Zone 2: Combustible gases, etc. not likely to be present under normal conditions

Zone 20: Where explosive concentrations of combustible dusts, etc., occur continuously or frequently under normal conditions.

Zone 21: Explosive concentrations of combustible dust, etc., may exist under normal conditions.

Zone 22: Explosive concentrations of combustible dusts, etc., which are unlikely to exist under normal conditions.

Explosive gas ignition temperature

Usually the ignition temperature of explosive gases is divided into six groups T1 ~ T6, it can be seen that the ignition temperature of T6 is the lowest, that is, the T6 group is the easiest to ignite, so if the electrical equipment to meet the T6 group of gas environment, but also inevitably meet the T1-T5 gas environment, that is, the higher the temperature group of the equipment the more secure (upward compatibility). (Reference: IEC60079, EN60079, NEC505)

Equipment protection level

In order to facilitate the selection of explosion-proof equipment, the Equipment Protection Level (EPL) is defined. Different types of explosion-proof equipment, as long as the EPL is the same its protection capability is the same by default, that is, can be used in the same explosion hazardous area. (Reference: IEC60079, EN standards and the ATEX directive of the European Union) The use of explosion-proof terminal boxes

Precautions for choosing explosion-proof junction box

1. Selection of explosion-proof class according to environmental requirements

In the selection of explosion-proof junction box, the first need to determine the explosion-proof level according to the requirements of the actual working environment. Different industrial places have different requirements for explosion-proof level, need to select the appropriate explosion-proof junction box according to the specific circumstances.

2. Knowledge of materials and levels of protection

Explosion-proof junction boxes are usually made of stainless steel, aluminum alloy or FRP, which have good explosion-proof performance and corrosion resistance. At the same time, it is important to understand the level of protection to ensure that it can effectively block the intrusion of dust, water vapor and corrosive gases.

3. Selection of appropriate sizes and fittings

When choosing explosion-proof junction box, you need to determine the appropriate size and accessories according to the number and size of equipment to be installed. Reasonable size and accessories can make equipment installation more convenient, but also can effectively save space.

The correct use of explosion-proof junction box

1. Regular inspection and maintenance

In order to ensure the proper functioning of the explosion-proof junction box, it needs to be inspected and maintained on a regular basis. To check whether the external surface of the junction box is damaged, whether the wiring is solid, and whether the explosion-proof equipment is in working condition. If problems are found, they should be repaired and replaced in a timely manner so as not to affect the safe operation of the equipment.

2. Compliance with rules of use

When using the explosion-proof junction box, it is necessary to strictly comply with the relevant regulations for use. Unauthorized disassembly or modification of the explosion-proof junction box is prohibited, so as not to damage the explosion-proof structure, resulting in safety accidents. At the same time, it is also necessary to avoid the use of ordinary equipment in flammable and explosive environments, and should use equipment with explosion-proof performance to ensure the safety of the production environment.

3. Enhancing staff training

For the use of explosion-proof junction box staff, need to strengthen the relevant safety training to improve their understanding of explosion-proof equipment and operating skills. Only professionally trained personnel can correctly use and maintain the explosion-proof junction box, effectively prevent and respond to possible safety incidents.