Future-Proofing Industrial Lighting: Smart Sensors in Explosion Proof vs Flame Proof Systems

Bridging Safety and Intelligence in Hazardous Environments

Introduction: The Convergence of Safety and Smart Technology

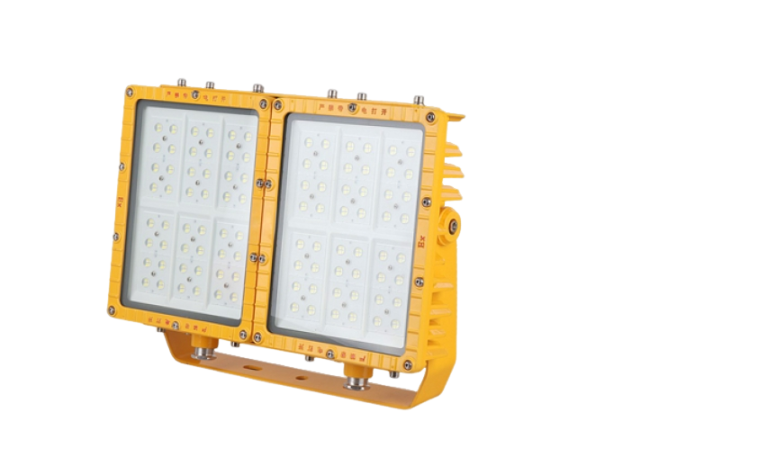

Industrial lighting in hazardous environments—such as oil refineries, chemical plants, and mining operations—has long prioritized explosion-proof (Ex d) and flame-proof (FLP) certifications to mitigate risks.

However, the integration of smart sensor technology is revolutionizing these systems, enabling predictive maintenance, real-time hazard detection, and adaptive energy management.

This article explores how intelligent sensor integration reshapes the capabilities of explosion-proof and flame-proof lighting, offering actionable insights for safety engineers and facility managers navigating Industry 4.0 demands.

1. Technical Challenges in Sensor Integration: Industrial Lighting

A. Explosion-Proof Systems: Pressure Containment vs Sensor Sensitivity

Thermal Management: Ex d enclosures, designed to withstand internal pressures ≥1.5MPa, often trap heat from high-power LEDs. Smart thermal sensors (e.g., infrared or fiber Bragg grating) must operate within strict temperature limits (≤85°C) to avoid false alarms while ensuring ATEX/IECEx compliance.

Signal Interference: Metallic enclosures can attenuate wireless signals. Solutions include wave-guide antennas and shielded Ethernet cables, as seen in offshore oil rig deployments where 5G-enabled sensors maintain connectivity in Zone 1 areas.

B. Flame-Proof Systems: Combustion Resistance vs Sensor Durability

Material Degradation: FLP coatings (e.g., nano-ceramic layers) resist external flames but may delamulate under humidity. Embedded humidity sensors with self-diagnostic algorithms alert operators to coating failures, as implemented in LNG storage facilities.

Dust Penetration: In Zone 22 grain silos, particulate-resistant optical sensors monitor lumen output degradation, triggering automated lens-cleaning mechanisms.

2. Smart Sensor Applications Across Industries

A. Predictive Maintenance in Petrochemical Plants

Vibration Analysis: Accelerometers in Ex d floodlights detect abnormal motor vibrations in pump systems, reducing unplanned downtime by 35%.

Gas Leak Detection: FLP fixtures with integrated methane sensors (≤1ppm sensitivity) activate ventilation systems within 0.5 seconds, as tested in a 2024 Texas ethylene plant upgrade.

B. Energy Optimization in Mining Operations

Adaptive Dimming: Motion sensors in explosion-proof LEDs adjust brightness based on worker proximity, cutting energy use by 50% in South African gold mines.

Battery Health Monitoring: IoT-enabled sensors in portable FLP lamps track lithium-ion charge cycles, preventing thermal runaway risks in underground coal mines.

3. Certification and Interoperability Hurdles

A. Divergent Standards

ATEX/IECEx: Require intrinsic safety (Ex ia) certifications for sensors in Zone 0, limiting power to <1.3W. Hybrid systems using energy-harvesting sensors (e.g., piezoelectric) bypass this constraint.

NEC/UL: Focus on physical durability over data integrity, creating gaps in hybrid gas/dust environments. Dual-certified systems, such as Valmet’s DCS-integrated lighting, combine UL 844 and IP66 ratings for North American refineries.

B. Data Security in IoT Networks

Encryption Protocols: AES-256 encryption in wireless sensor networks prevents cyber intrusions, critical for lighting systems linked to plant-wide DCS platforms.

Edge Computing: Onboard processors in FLP fixtures analyze sensor data locally, reducing cloud dependency and latency in remote offshore platforms.

4. Future Trends: AI and Sustainable Materials

A. AI-Driven Hazard Prediction

Machine learning models trained on thermal imaging data from FLP fixtures predict equipment failures 72 hours in advance, as piloted in a Norwegian LNG terminal.

Digital twin simulations optimize sensor placement in Ex d systems, reducing physical testing costs by 40%.

B. Eco-Friendly Innovations

Self-Healing Polymers: Microcapsules in sensor housings repair cracks caused by thermal cycling, extending maintenance intervals by 50%.

Bio-Based Sensors: Graphene oxide sensors derived from lignin offer flame resistance without halogenated compounds, aligning with EU REACH regulations.