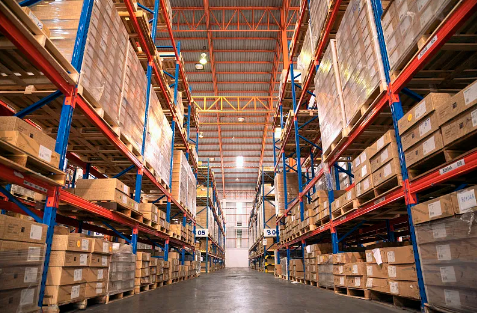

In the operation of enterprises, warehouse management plays a very important role and is the cornerstone of ensuring the continuous stability of product quality. Once problems occur, it will directly cause economic losses and even bring adverse effects to the brand. Now let’s talk about those things in warehouse management that cannot be ignored.

The warehouse should have appropriate warehouse management systems and be staffed with professional personnel. Stored items should be classified and placed on shelves. For small parts, storage boxes can be added to the shelves. Labels should be used to identify the model and quantity of each item for easy management and query. Regular inspections of stored items should be conducted to ensure their performance and condition are normal. During the management process, ensure that the accounts, physical inventory, and cards are consistent.

The warehouse environment should be well-ventilated, clean, and free of corrosive gases. In the explosion-proof industry, there are some special requirements that must be followed. For example, the storage requirements for metal parts, electronic components and circuit board assemblies, rubber parts, potting compounds/adhesives/potting agents are all different.

1. For metal parts such as explosion-proof enclosures, special attention should be paid to the protection of the explosion-proof surface during storage. When storing, the explosion-proof surface should face upwards. During transportation, handle them with care. The explosion-proof surface should be protected with rubber pads or other sturdy and soft materials to prevent accidental bumps.

2. Electronic components and circuit board assemblies have higher requirements for storage conditions. Firstly, the temperature and humidity should be moderate, generally recommended to be controlled at 20-25 ℃ and 40-60% RH respectively, to prevent moisture or overheating. Secondly, anti-static measures should be taken, such as using anti-static packaging materials or anti-static racks for storage, to prevent static discharge from damaging the components and circuit boards. Vacuum packaging or nitrogen-filled packaging can also be considered. Finally, they should be kept away from magnetic field interference to prevent damage to sensitive components such as transistors.

3. Rubber parts should be stored away from light, especially avoiding strong sunlight and ultraviolet rays. The storage temperature should be between 5-25 ℃. The storage period should not be too long to avoid aging and affecting the elasticity and service life of the rubber parts.

4. Potting compounds/adhesives/potting agents should be stored as per the instructions. Generally, they should be kept in a dry, well-ventilated, cool, and insulated place, away from direct sunlight and open flames. The shelf life of these items is usually half a year or one year. Regular checks should be made to ensure they have not expired.

From a safety perspective, flammable and explosive items should be stored in separate explosion-proof boxes. Fire hydrants, fire extinguishers and other fire-fighting equipment should be provided in the warehouse.