Explosion proof led lamp in the railroad safety lighting in the role of the fundamental

First, why the railroad system must use explosion-proof lights? –Safety regulations and operational needs of the double drive

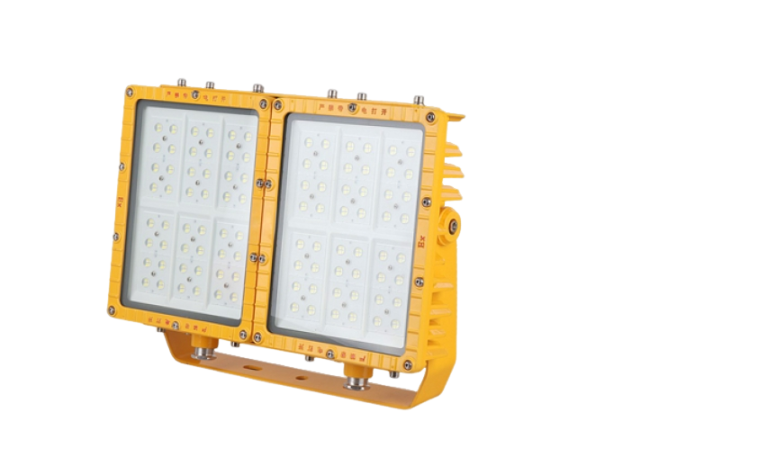

In the railroad transportation system, Explosion proof led lamp are the core equipment to ensure operational safety. According to the “Railway Electricity Design Code” requires that involves locomotive maintenance depot, oil storage areas, signaling equipment and other explosive gases or dust places, must be equipped with Ex d II CT6 and above explosion-proof grade lighting equipment.

For example, the locomotive diesel engine maintenance area combustible gas concentration of about more than the lower explosive limit [LEL] 5%, the traditional lamps and lanterns to produce 0.02 joules of electric spark that may cause an explosion. Explosion proof led lamp approved triple protection mechanism to completely eliminate potential hazards:

Explosion-proof structure: 8mm die-casting aluminum alloy shell can withstand 15MPa explosion impact, to prevent the internal spark leakage

Intrinsically safe circuit: constant-current drive technology to limit the circuit energy below 0.19mJ

Increased safety sealing: silicone rubber sealing ring and precision joint surface [tolerance ≤ 0.05mm] to implement IP65 protection level, effectively isolate the oil and gas infiltration

Actual cases show that a railroad grouping station using 150W LED Explosion proof led lamp, the annual failure rate decreased by 92%, maintenance costs reduced by 80%.

Second, explosion-proof lights in the railroad system core application scenarios and technical guidelines

1. Railway tunnel lighting

Ex d IIC T6 explosion-proof grade flood-type lamps and lanterns, installation spacing of 15-20 meters, covering a range of 30 meters recommended configuration 120 ° wide-angle lens + Ra> 90 high color rendering design, to facilitate track inspection and equipment maintenance.

2. Locomotive maintenance depot and oil storage area

Need to meet the WF2 anti-corrosion grade, the shell using high-pressure plastic spraying process, salt spray test ≥ 1000 hours emergency lighting system needs to be equipped with lithium iron phosphate batteries, power outages to maintain the 90 minutes 1lx cornerstone illuminance.

3. Signal equipment room and distribution room

Lamps and lanterns should have anti-electromagnetic interference characteristics, in line with EN 50121 railroad electromagnetic compatibility guidelines intelligent products can be integrated with temperature and humidity sensors, real-time monitoring of environmental parameters and linkage of ventilation systems.

4. Emergency repair and night operation

Mobile Explosion proof led lamp equipped with DC24V lithium batteries, endurance time ≥ 15 hours [bright mode] integrated wheels and railroad track adapters, can be deployed at high speed in complex terrain.

Third, the railroad explosion-proof light selection 5 technical guidelines

1. Certification compliance must be approved CNEX explosion-proof certification [Ex d II CT6] and the railroad industry access testing, give priority to IECEx / ATEX dual-certified products

2. Optical performance improvement advocate luminous efficacy ≥ 120lm / W, color temperature selection 4000-5000K neutral white light, to avoid glare interference with the operator’s line of sight environmental adaptability

3. the operating temperature range should cover -40 ℃ to +80 ℃ anti-vibration performance to meet the IEC 60068-2-6 guidelines [5Hz-150Hz, three-axis vibration test for 30 minutes each].

4. Intelligent control system to help DALI dimming protocol and railroad BMS system linkage, energy saving rate of up to 40% integrated fault self-diagnostic module, can be 14 days in advance to warn of potential failures

5. full life cycle cost of 100W LED Explosion proof led lamp, for example, 5 years total cost than traditional lamps and lanterns to reduce 65% [including electricity, maintenance and replacement costs].

Fourth, technological innovation: explosion-proof lights in the field of railroads, three major breakthroughs

1. Composite energy supply system

2025 launch of vibration power generation type Explosion proof led lamp, approved the collection of train energy to implement off-grid power supply, has been implemented in the pilot section of the Beijing-Shenzhen high-speed rail zero cable wiring, saving 1.2 million yuan in annual power costs

2. Intelligent spectral monitoring technology

The use of 430nm wavelength LED Explosion proof led lamp, synchronized detection of methane concentration [sensitivity 0.1% VOL], and gas detection system linkage to form a safety protection network

3. Digital twin operation and maintenance platform

Each lamp implanted with a unique ID chip, approved 3D modeling is implemented:

Fault prediction accuracy ≥ 92% maintenance response time shortened from 48 hours to 2 hours

Fifth. Successful cases: a high-speed rail hub station lighting transformation benefit analysis

Zhengzhou East Station after the implementation of explosion-proof lighting upgrade project:

Safety indicators: zero lighting-related accidents for three consecutive years

Economic benefits: annual electricity cost savings of 5.3 million yuan, equipment replacement cycle extended from 3 years to 10 years

Operation and maintenance efficiency: intelligent management system to reduce the frequency of manual inspections 75

Sixth, the future momentum: railroad Explosion proof led lamp technology development in three major directions

Material innovation graphene heat dissipation module to reduce the weight of the lamps and lanterns by 40%, thermal conductivity efficiency increased by 300% energy independent photovoltaic – vibration composite energy supply system to implement 100% off-grid operation AI fusion approves the machine learning to improve the light strategy, dynamically match the train scheduling cycle

Amasly Lighting, as a leading explosion-proof lighting solution provider, has provided customized services for many high-speed rail lines.

Our RailSafe series products are approved by 97 extreme environment tests and equipped with:

Intelligent Operation and Maintenance Platform [Failure Response <2 hours] Full Life Cycle Cost Simulation System Free Railway Lighting Safety Assessment

Contact us to get the Railway Explosion-proof Lighting Upgrade Program now!