Class 1 division 1 explosion proof light in the shipyard lighting in the fundamental application and technological innovation

Introduction: shipyard lighting specialties and Class 1 division 1 explosion proof light core value

Shipyards as a typical heavy industrial scene, its production environment is often accompanied by flammable and explosive gases [such as paint volatiles, welding gas], high humidity, salt spray corrosion and other risks.

Traditional lighting equipment is difficult to meet the safety and efficiency needs of such high-risk places, and Class 1 division 1 explosion proof light with its unique explosion-proof structure, corrosion resistance and high reliability, into the core of the shipyard lighting program.

In this paper, from the application scenarios, technical advantages, selection points and future momentum and other dimensions, in-depth analysis of explosion-proof lights in the shipyard in the fundamental role.

First, the shipyard explosion-proof lights core application scenarios

1. hull welding and painting workshop

Ship hull welding process produces arc sparks and painting workshop volatile organic solvents [such as toluene, acetone] is very easy to form explosive gas mixtures.

Class 1 division 1 explosion proof light approved explosion-proof structural design [such as explosion-proof stops, threaded explosion-proof], to ensure that the lamps and lanterns probably produce internal sparks and high-temperature surfaces and external hazardous environments are isolated from the root cause to avoid the risk of explosion.

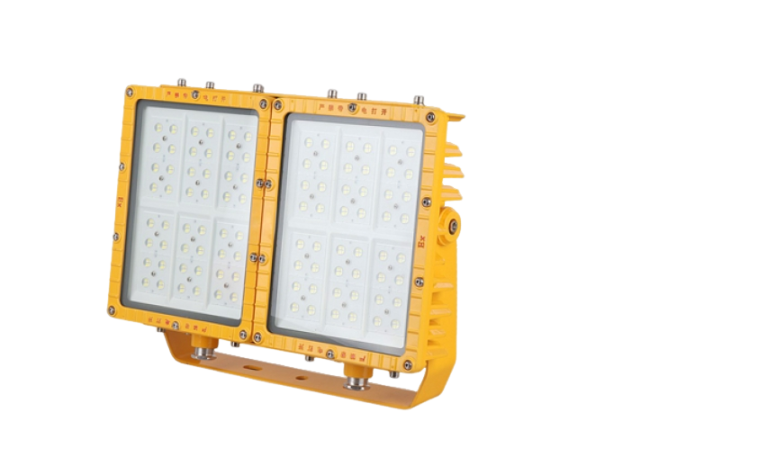

Let’s say, LED explosion-proof floodlight using high-strength aluminum alloy shell and tempered glass cover, protection level up to IP66, can resist welding spatter and chemical corrosion.

2. Cabin interior and confined space

Poor ventilation inside the cabin, easy to accumulate combustible gases or dust. Class 1 division 1 explosion proof light with efficient heat dissipation design and low surface temperature characteristics [in line with the T1-T6 temperature group], can be adapted to the confined space for a long time lighting needs.

For example, 50W-100W LED explosion-proof ceiling light is approved with open cooling fins and aluminum reflector, which ensures that the lamps operate stably at extreme temperatures from -30℃ to 60℃, and reduces the frequency of maintenance.

3. Dock and open area

Shipyards and open-air areas need to deal with salt spray, rain and other environmental erosion. Class 1 division 1 explosion proof light anti-corrosion grade [such as WF2] and the surface of the electrostatic spray process, can effectively resist metal oxidation and salt spray corrosion.

For example, wall 60W LED explosion-proof floodlights with stainless steel fasteners and silicone rubber seals, protection performance of up to 10 years or more, significantly reducing equipment replacement costs.

Second, explosion-proof light technology advantages and performance breakthroughs

1. Energy-efficient light source and long life design

Modern Class 1 division 1 explosion proof lamp commonly used LED technology, light efficiency up to 110lm / W or more, compared with the traditional metal halide lamps, energy saving 60% -70%.

30W explosion-proof LED lights, for example, its light source life of more than 50,000 hours, light decay is less than 3 ‰, significantly reducing the loss of downtime due to frequent replacement of lamps and lanterns.

2. Multiple safety protection mechanisms

Explosion-proof structure: explosion-proof cavity and safety-enhanced circuit design, in line with the Exd II CT6 explosion-proof guidelines, suitable for IIA, IIB, IIC explosive environments. Intelligent care system: built-in over-voltage, over-current and short-circuit care module to avoid failure caused by voltage fluctuation.

3. Flexible installation and customized solutions

Class 1 division 1 explosion proof lamp help ceiling, wall, boom, flange and other installation methods to adapt to the complex space structure of the shipyard.

For example, explosion-proof floodlights can be configured with guardrail-type bracket to meet the deck and overhead lighting needs; and explosion-proof ceiling lights are suitable for barrier-free installation of low cabins.

Third, the shipyard Class 1 division 1 explosion proof light selection and maintenance guidelines

1. Selection of the basic parameters

Power fit: according to the area of the operation area to choose 20W-150W power range, such as 30W for narrow cabins, large dockyard selection of more than 100W floodlights.

Protection level: IP65/IP66 waterproof and dustproof and WF2 anti-corrosion performance is preferred to adapt to the coastal high humidity environment.

Color temperature and color rendering: recommended 4500K-6500K positive white temperature, color rendering index Ra>80, to ensure that the welding and testing operations color reproduction.

2. Maintenance and safety specifications

Regularly check the sealing: the aging of the rubber sealing ring probably reduces the protective performance, need to be replaced every 2 years. Strictly prohibit operation with electricity: maintenance needs to cut off the power supply, to avoid accidents caused by electric sparks.

Fourth, the industry case: explosion-proof lights in the shipyard practical benefits

Case 1: a large shipyard painting workshop renovation

50W LED explosion-proof floodlights to replace the traditional high-pressure sodium lamps, lighting uniformity increased by 40%, the annual energy consumption reduced by 35%, and did not occur due to the lamps and lanterns triggered by potential safety hazards.

Case 2: offshore drilling platform lighting upgrade

Deployment of 80W explosion-proof floodlights, the average trouble-free operation of the equipment for more than 7 years, maintenance costs reduced by 60%, while approving the modular design to implement high-speed fault replacement.

Fifth. Future momentum: intelligent and green development

Intelligent Control Integration: Approval of the Internet of Things technology to implement Class 1 division 1 explosion proof light remote dimming, fault warning and energy consumption monitoring, to enhance management effectiveness.

Material innovation: nano-coating and magnesium alloy applications will further reduce the weight of the lamps and enhance corrosion resistance.

Light environment improvement: adaptive optical system can dynamically adjust the light intensity and angle according to the operational needs, reducing glare interference.

Conclusion: Class 1 division 1 explosion proof lamp – the cornerstone of shipyard safety lighting

Class 1 division 1 explosion proof light is not only a shipyard safety production security, but also to enhance operational efficiency and reduce operating costs of core equipment. Along with LED technology, intelligent control and the development of new materials, explosion-proof lights will play a more long-term value in the field of shipbuilding.

Enterprises need to combine specific scenes to choose the appropriate products, and lay a scientific maintenance system to maximize the benefits of the equipment.