I. Application of explosion-proof cables:

Explosion-proof cables are widely used in electrical equipment and systems in hazardous environments such as petroleum, chemical, coal mine and ship to ensure safety and reliability in the workplace. They are also used in the power supply lines and control lines of fire pumps, sprinkler pumps, fire elevators, power supply and control lines of fire shutter doors, electric fire doors, smoke exhaust system fans, smoke exhaust valves, fire dampers, security CCTV lines in high-rise buildings and airports, subways and other important facilities, centralized power supply of emergency lighting lines, control and protection of power supply lines and so on.

Explosion-proof cables differ significantly from conventional cables in a number of ways, mainly in their design, materials and application environments.

Here is a detailed comparison:

1. Explosion-proof cables are designed with special materials and structures that can prevent arcs, sparks and other situations that may cause explosions. This design ensures that even when a short circuit or electrical spark occurs, the surrounding flammable and explosive gases will not be ignited.

2, explosion-proof cables are usually made of flame-retardant materials, which can slow down the spread of fire in the event of a fire. This makes explosion-proof cables safer and more reliable in hazardous environments.

3, explosion-proof cable can withstand high-temperature environment, not easy to melt or deformation. This characteristic makes it still maintain stable working performance under high temperature conditions.

4, explosion-proof cable has good shielding performance and anti-static properties, can effectively isolate the external electromagnetic field interference, radio frequency interference and electric field coupling. These characteristics are particularly important for communication, monitoring, detection, alarm and control systems.

5, explosion-proof cables have high mechanical strength and can withstand large tensile forces and pressures. This allows them to maintain good physical properties in a variety of harsh environments.

6, explosion-proof cables are usually corrosion-resistant and can be used in corrosive media for a long time. This characteristic makes it suitable for electrical equipment and systems in hazardous environments such as petroleum, chemical industry, coal mines, ships and other hazardous environments.

7, explosion-proof cables are characterized by low capacitance and low inductance, which helps to reduce energy storage and improve the stability of signal transmission.

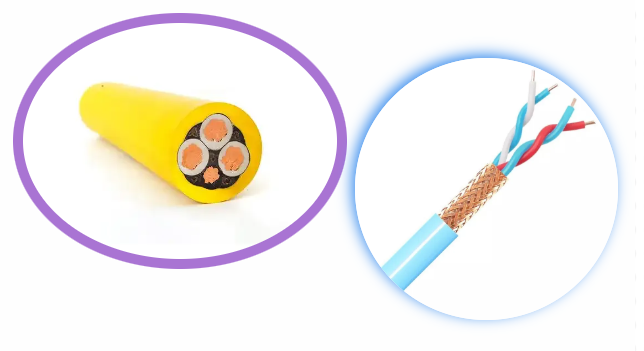

8. The outer layer of the explosion-proof cable is made of special sealing material, which can effectively prevent water, dust, etc. from entering into the inner part of the cable and ensure the long-term stable operation of the cable. In addition, light blue markings are set at the entry and exit positions to clearly distinguish the cables or wires of intrinsically safe circuits.

II. explosion-proof cable how to realize explosion-proof:

The special materials and structural design of explosion-proof cables realize their explosion-proof performance in many ways. First of all, in structural design, explosion-proof cables focus on tensile strength, pressure resistance and sealing performance, and adopt high-strength armor layer and protective layer to ensure the stable performance of cables in hazardous environments. In addition, the design of the introduction device is also very important, usually including seals, gaskets, plugs, compression nuts and cables and other components, the selection and combination of these components can effectively prevent explosive gases from entering the cable interior.

In terms of material selection, explosion-proof cables usually use high-temperature-resistant and corrosion-resistant materials to manufacture insulation and sheath layers to improve the durability and safety of cables. For example, the irradiation cross-linking process can enhance the insulation performance and mechanical strength of the cable.

III. the advantages of explosion-proof cable:

Explosion-proof cables in high-temperature environments, how the performance, compared with conventional cables have what advantages

1, explosion-proof cables usually use silicone insulation and copper conductors, these materials can withstand high temperatures. For example, the maximum conductor temperature of some explosion-proof cables can reach 180 ° C, and for a short period of time can even reach 220 ° C. This high temperature resistance makes the explosion-proof cable in the high temperature environment can still work stably.

2, the internal structure of explosion-proof cable is more strict than ordinary cable, including multi-layer structure such as fire-resistant layer, insulation layer, metal layer and explosion-proof layer. These multi-layer design not only improves the fire resistance and explosion resistance of the cable, but also enhances its stability under high temperature conditions.

3, explosion-proof cables have good shielding and anti-static properties in addition to the basic protection and corrosion resistance characteristics. These characteristics further ensure the safety and reliability of the cable in the high temperature environment.

4. Explosion-proof cables use materials such as silicone and copper conductors that have excellent high-temperature resistance and flame retardancy. In addition, explosion-proof cables may also use halogen-free materials, which not only helps to prevent the occurrence of fire, but also reduces the emission of harmful gases.

5, explosion-proof cables are suitable for special environments where flammable and explosive mixtures need to be prevented from contacting electrical components that may cause an explosion. This design makes it effective in preventing potential safety hazards even in high temperature environments.

6, explosion-proof cable in the high-temperature environment, excellent performance is mainly reflected in its high-temperature resistance, strict structure, multiple protective features and the choice of high-quality materials.

VI. explosion-proof cable shielding performance and anti-static properties of the performance

Explosion-proof cable shielding performance and anti-static performance in what aspects?

1. Shielding performance:

1-1, explosion-proof cable has good shielding performance, which is mainly due to its enhanced shielding layer design. This design can effectively resist the influence of external magnetic fields, the influence of microwave radio frequency and electrostatic field coupling.

1-2, explosion-proof cable has low capacitance and not easy to store charge characteristics, which makes it outstanding performance in the electromagnetic interference environment, can effectively reduce the interference in the signal transmission process.

2. Antistatic properties:

Explosion-proof cables also have good anti-static properties. This means that during use the cable will not be dangerous due to static build-up, which is particularly important in flammable and explosive environments.

V. explosion-proof cable how to improve the stability of signal transmission

How can the low capacitance and low inductance characteristics of explosion-proof cables improve the stability of signal transmission?

The low capacitance and low inductance characteristics of explosion-proof cables significantly enhance the stability of signal transmission. These characteristics are mainly realized through the following aspects:

1. Reduce signal attenuation:

Low capacitance means less signal attenuation due to capacitive effects during signal transmission, thus maintaining signal integrity and stability.

2. Reduce electromagnetic interference:

Low inductance reduces the inductive effects of electromagnetic fields, making the cable more resistant to interference in complex electromagnetic environments. This helps ensure signal stability and accuracy during transmission.

3. Excellent shielding performance:

Explosion-proof cables usually have good shielding properties, which further enhances their immunity to interference. The combination of low capacitance and low inductance enables the cables to be more effectively shielded from external electromagnetic interference, thus improving the reliability of signal transmission.

4. Suitable for high demand occasions:

Due to these characteristics, explosion-proof cables are particularly suitable for petroleum, chemical, electric power, gas engineering and mining, where there is a danger of explosion, as well as for other occasions where explosion-proof safety requirements are high. These environments often have extremely high requirements for the stability and reliability of signal transmission.