What’s the Difference between explosion-proof grands and ordinary grands ?

Explosion-proof glands are a kind of explosion-proof accessories used on cables with high requirements, which can be installed in the connection between explosion-proof cable ports and explosion-proof electrical equipment, play a role in introducing cables and fixing positions to achieve sealing and explosion-proof function, with superior performance of explosion-proof, safe and reliable structure, simple and convenient installation, and high advantages of protection level. Widely used in petroleum, chemical and other electrical safety explosion-proof places, especially for offshore platforms, ships need electrical explosion-proof places.

1 Difference between explosion-proof glands and ordinary glands

It’s not really hard to tell the difference between the two.

First: the explosion-proof glands are made of metal, the general choice of stainless steel, carbon steel, or brass. And the common granular head is plastic.

Second: explosion-proof glands have explosion-proof documents, test reports, explosion-proof function, more professional, rigorous. And the ordinary head is no such documents.

Thirdly: the price of ordinary glands is cheap, explosion-proof glands are costly and expensive.

Fourth: the two use of the industry is not the same. Ordinary glands are suitable for ordinary distribution boxes, distribution cabinets, control boxes, switchboards, lamps and lanterns wire and cable fixed, effectively clamping the cable to play a waterproof sealing effect. Explosion-proof glands are suitable for explosion-proof distribution boxes, explosion-proof instrumentation boxes and other explosion-proof equipment, most of which are used in chemical industry, the most important thing is to play an explosion-proof, isolation, sealing effect.

The most important four differences between the two speak separately to elaborate the end, and then say that their common role is to play a sealing role in clamping, ordinary Glen head with waterproof and dustproof role, explosion-proof Glen head in addition to the advantages of waterproof and dustproof, but also has the role of anti-explosion, corrosion prevention, generally used in explosion-proof equipment.

Therefore, to see whether the explosion-proof glands, first of all see whether the metal material, and secondly, the most obvious and direct way or from the components to see whether there is “Ex” logo. Regardless of which type of glands, special industries, flammable and explosive explosions, easy to environmentally corrosive places need to use high-end high-quality glands, such as 304, 316 stainless steel explosion-proof glands.

2 Explosion-proof spare connecting pipe and the use of granular head related to the instructions

Explosion-proof flexures are designed for explosion-proof meters, and many features are redundant and cumbersome to use for intrinsically safe meters and applications that do not require explosion-proofing.

Glen head, also called cable fixing head, is installed in the connection between the cable and electrical equipment, and plays the role of introducing the cable, fixing the position, sealing and flameproofing.

Generally speaking, the safety instrument can play a fixed, waterproof, sealing, fire-retardant itself on the line. Engineering plastics will be able to meet the requirements; the explosion-proof instrumentation, sometimes also need to have the formation of a pressure relief channel, the role of energy absorption, with all these features of the Grand Head is usually made of metal.

After the instrument wire is led out from the glands, leave a length of less than one meter in the space, and then put it through the pipe or into the sink. It is best to use the glands to fix the inlet of the pipe and the sink (other measures are also possible).

Signal wires other than current, resistance, and switching, if not shielded, it is best not to use the glands (it is best to use shielded wires), and the use of glands for compensating wires should be done with caution.

If you use armored cable, only with armored cable sealing joints, do not need to flex pipe, armored cable into the junction box is also through the armored cable sealing joints; if it is not armored cable, with cable sealing joints + flex pipe, flex pipe and tee (for drainage) connection, tee and through the pipe connection. The feeder pipe is connected to the cable sealing connector of the junction box through the flexible pipe. The feed line of the junction box is at the bottom of the box, so generally there is no need to add a tee for drainage.

Cable sealing connector is a cable introduction device, for explosion-proof instrumentation, the purpose is to play the role of explosion-proof with the instrument itself. There is no explosion-proof requirements at the penetration pipe, with cable sealing joints waterproof, some of the material is too big to use.

gland is the internationally recognized cable introduction device. In China there are still other forms of cable clamping joints. For example, Nanyang Explosion-proof Motor Factory has always insisted on using their cable outlet hopper, which is divided into two types: flared and threaded. For electrics, they sometimes do not use glands, but threaded mouth + sealing rubber ring. Both of these practices are in line with national explosion-proof norms.

3 Explosion-proof Granular Head What to pay attention to when installing

1, in and out of the line as far as possible to use the bottom in and out of the type, can effectively prevent rain and other into the explosion-proof distribution box.

2, non-armored cables, can be used to sealing ring type cable introduction device, its outer diameter and sealing ring inner diameter to match, to ensure that the elastic sealing ring can effectively press the cable, squeezed into the inner hole of the device, or the sealing filler must be through the cable sealed to ensure good sealing performance. Armored cables shall be guided by a press-open function guide device.

3. One hole of the elastic seal shall seal one cable, one cable introduced only one. Cable cross-section must be round. When the outer diameter of the cable is greater than 20mm, the compression device shall adopt the anti-pull-off mechanism.

4. Explosion-proof threads with threaded lead devices are at least 6 buckles and at least 8mm long.

5, filler sealing type introduction device is a thermosetting mixture of filler filled into the introduction of the device, its zui small axial length should be 20mm, filler curing type need to be non-combustible or flame-resistant, no heating can be filled, room temperature can be cured. Explosion-proof distribution box in and out of the cable hole sealing and explosion-proof face has a certain effect on the explosion-proof effect.

4 without temperature group explosion-proof glands, is it fake?

An explosion-proof gland head labeled ExdⅡC Gb/ExtD A20 with no temperature group, is it a fake?

I. First of all, understand a few of the art 7 phrases in the explosion protection regulations:

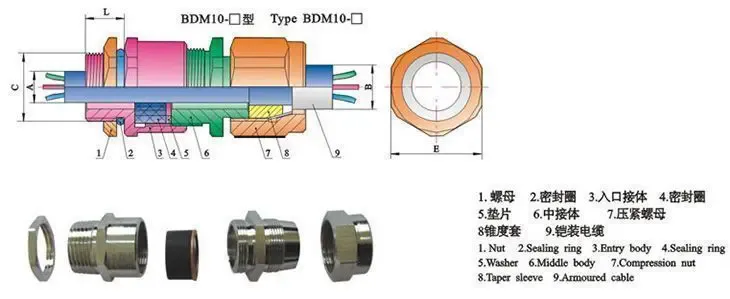

3.10 Cable introduction device cable gland

A device which permits one or more cables or fiber-optic cables to be routed inside the enclosure of Ex electrical equipment in such a way as to maintain the corresponding explosion-proof type and to provide a degree of strain relief.

NOTE: See Figure A.1 for an illustration of the term cable gland.

3.10.4 Ex equipment cable introduction device Ex Equipment cable gland and equipment shell separate test, but with Ex equipment explosion-proof certificate of conformity, is expected to be installed on the Ex equipment shell cable introduction device. Note: Does not exclude the cable introduction device to obtain Ex component explosion-proof certificate of conformity.

3.46 Maximum surface temperature

The maximum temperature attained by any part or any surface of Ex equipment when operated under the most unfavorable operating conditions (but within specified tolerances).

3.67 I temperature class

The classification based on the maximum surface temperature of the Ex equipment is related to the specific explosive atmosphere in which the Ex equipment is intended to be used.

5.6.1 General Note: Cable introduction devices are normally not marked with a temperature group or operating ambient temperature range. The rated operating temperature of the cable introduction device, if not marked, defaults to an operating temperature range of -20°C to +80°C. If different operating temperatures are required, it is appropriate to note that the cable entry device and its associated components shall be suitable for such use.

Conclusion: This explosion-proof Glen head alone from the lack of standard temperature grouping, can not be judged as a fake.