Division 1 explosion proof light in coal mine safety lighting applications

First, why do you have to choose professional Division 1 explosion proof light in coal mines?

In the special environment of coal mining, explosion-proof lights have become a rigid demand to ensure production safety. According to the International Mine Safety Association [IMSA] 2023 annual report shows that 35% of the world’s underground accidents and lighting system failure there is a direct correlation.

Traditional lighting equipment in the methane concentration of more than 5% of the confined space, only 0.02 Joule electric spark can trigger an explosion, which is the fundamental value of the existence of professional explosion-proof lights.

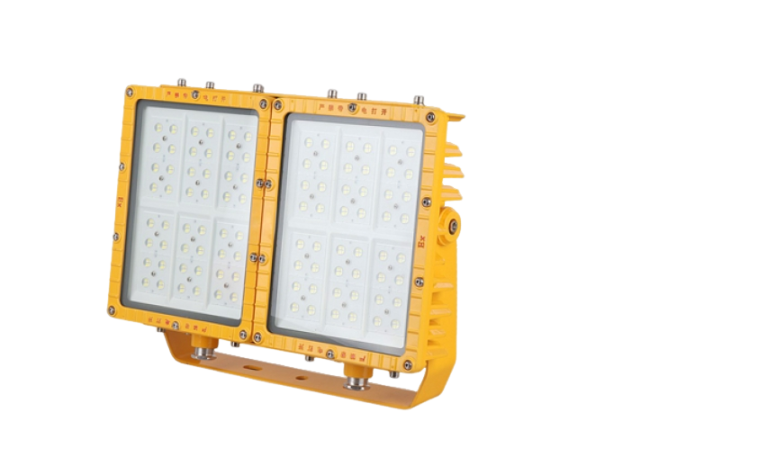

Coal mine Division 1 explosion proof light must be approved IECEx/ATEX double certification, its explosion-proof structure using triple protection mechanism:

Explosion-proof shell: 8mm thick aluminum alloy shell can withstand 15MPa explosion pressure

Intrinsically safe circuit: limit the circuit energy below the minimum ignition energy

Increased safety protection: the fundamental joint surface precision machining to 0.05mm tolerance

Second, intelligent Division 1 explosion proof light technology breakthrough: from the cornerstone lighting to digital mining

Modern explosion-proof lights have broken through the traditional lighting category, in Shanxi Yangquan Coal Group intelligent transformation, equipped with 5G module Division 1 explosion proof light and lanterns to implement:

Real-time collection of temperature and humidity in the working face, gas concentration data automatically adjust the 3000-6500K color temperature to adapt to different operating scenes approved Mesh networking to build underground positioning system [accuracy of ± 0.5m].

Third, the golden rule of coal mine Division 1 explosion proof light selection: 5 fundamental indicators

1. Explosion-proof grade certification: must hold Ex d I Mb certification [China Coal Safety Mark + international certification].

2 optical performance configuration: advocating the choice of 120 ° wide-angle lens + anti-glare design machinery

3. Protection: Impact resistance must reach IK10 [5 Joule impact test]. 4.

4. Emergency lighting system: automatic switching of lithium iron phosphate battery power supply after power failure.

5. Convenience of maintenance: modular design helps high-speed disassembly and assembly underground [average maintenance time <15 minutes].

Inner Mongolia Ordos a coal mine measured data show that the use of new LED explosion-proof lights:

Lighting energy consumption reduced by 67% [annual electricity savings of more than 2.8 million yuan] equipment failure rate decreased by 82% roadway inspection efficiency increased by 45

Fourth, Division 1 explosion proof light installation and maintenance of the whole process specification

According to GB 3836.15-2017 guidelines, explosion-proof light installation must be followed:

Pre-embedded parts load-bearing test [1.5 times the safety factor] cable introduction device secondary blocking [using Ex special sealant] regular maintenance of explosion-proof surface [quarterly detection of the gap between the joint surface].

Common Maintenance Mistakes Warning:

× Wiping the explosion-proof glass with ordinary cleaners.

× Replacement of non-original light source modules without authorization

× ignore the grounding resistance test [should be <4Ω].

Fifth. Global coal mine lighting development momentum: Division 1 explosion proof lamp technology revolution

The International Mining Complex 2024 [IMC] reveals three major directions of innovation:

Self-supply energy system: integrated vibration power generation device, using the energy of the passage of mine cars

Digital twin application: each Division 1 explosion proof light laying 3D operation and maintenance models

Intelligent Spectroscopy: Approving light wavelengths to detect changes in gas concentration.

A multinational mining group measured cases show that the adoption of AI explosion-proof light system:

Equipment lifecycle extended to 80,000 hoursPreventive maintenance accuracy increased to 92%Accident rate related to underground lighting zeroed out

Amasly Lighting, the innovation leader in explosion-proof lighting, has supplied coal mine lighting solutions to many countries around the world.

Our Ex Series products have been approved for 83 rigorous tests and are equipped with an intelligent lighting management system that allows us to customize a complete mine lighting upgrade.