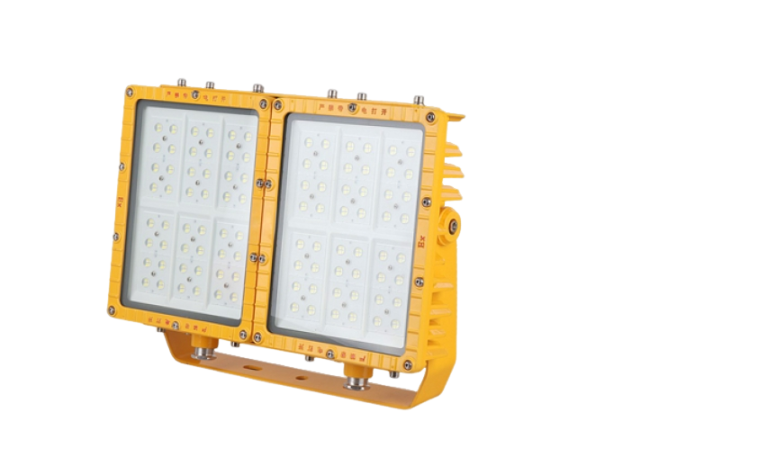

ATEX explosion proof light 60w in the port lighting core applications and safety performance analysis

Introduction: Port lighting special challenges and ATEX explosion proof light 60w suitability

As the core hub of logistics and energy transport, harbours often face multiple risks such as oil and gas evaporation, humidity and salt spray, and mechanical collision.

ATEX explosion proof light 60w with high explosion-proof rating (e.g. Ex d IIB T4) and IP66/67 protection of the European Union ATEX certification has become the preferred solution for the lighting of high-risk areas in ports.

Its 60W power design combines high luminous efficacy and low energy consumption to meet the lighting needs of large operating areas, while reducing operating costs.

First. The port why need ATEX explosion proof light 60w?

1. Explosive gas environment high-risk port oil storage areas, loading and unloading terminals and other areas prone to the accumulation of flammable gases [such as methane, propane], ordinary lamps and lanterns are prone to spark explosions.

ATEX explosion proof light 60w approved explosion-proof cavity and increased safety structure design, effective isolation of internal arc and high temperature, suitable for Zone 1/Zone 2 hazardous areas.

2. Severe environmental resistance salt spray corrosion, rain immersion and -40 ℃ ~ 60 ℃ temperature difference is a common challenge in the harbour.

The lamp adopts 316 stainless steel shell and vacuum coating process, corrosion resistance up to WF2 grade, with tempered glass transparent cover, to ensure long-term stable operation.

3. High performance lighting needs 60W LED chip luminous flux up to 5500 ~ 13200 lumens, wide coverage and uniform illumination, suitable for cargo ship decks, container yards and other large space operation lighting, luminous efficacy than traditional lamps and lanterns to enhance more than 60%.

Second, Amasly ATEX explosion proof light 60w technical advantages of analysis

1. explosion-proof and safety performance double certification guarantee: approved ATEX 2014/34/EU and IECEx guidelines, explosion-proof grade up to ExdIICT6, suitable for IIA/IIB/IIC gas environment.

2. Intelligent sensing design: some models integrated with water touch switch and gravity sensing, automatically activated in the event of water, off from the water surface, eliminating the risk of misuse.

3. Structural design and durability of three independent cooling chambers: Separate light source, power supply and wiring chambers to reduce component temperature rise and extend the life to 50,000 hours.

4. Impact-resistant housing: die-cast aluminium with honeycomb heat dissipation rib, can withstand 76m drop and mechanical collision.

5. Flexible installation and intelligent control to help boom, wall-mounted, flange and other multi-scenario installation, suitable for dock cranes, warehouse roofs and other complex structures.

6. optional emergency lighting module, automatic switching after the main power interruption, endurance ≥ 20 hours, to protect the safety of night operations.

Third. Typical application scenes of ATEX explosion proof light 60w in the port

1. oil loading and unloading area and storage tank area explosion-proof grade ExdIICT6 can cope with T1-T6 temperature group, to ensure that the oil and gas mixed environment without spark lighting, to avoid explosion accidents.

2. Container terminals and shore crane operation areas with high protection level [IP66/IP67] against heavy rain and waves, wide voltage design [AC100V-220V] to adapt to power fluctuations in the harbour.

3. Port emergency channel and life-saving equipment are equipped with gravity-sensing and water-touch switch lifebuoy lights, which are automatically lit in case of danger, in line with SOLAS/MED maritime safety guidelines.

Fourth, the selection guide: how to match the port needs ATEX explosion proof light 60w?

1. Certification compliance: Priority is given to ATEX, IECEx and USCG certified products to ensure that they are common to ports around the world.

2. Environmental suitability: high salt spray areas need to use WF2 anti-corrosion grade and 316 stainless steel; vibration-frequent areas advocate the installation of boom and equipped with anti-vibration structure.

3. Energy efficiency parameters: luminous efficacy > 120lm / W, colour temperature 4000K-5000K lamps and lanterns can balance the visibility and crew comfort.

Fifth. Future momentum: intelligent and green port construction

Along with the port digital upgrading, integrated light sensing and Internet of Things ATEX explosion proof light 60w will become mainstream.

For example, the approval of the wireless control system to adjust the brightness, or real-time monitoring of the status of the lamps and lanterns and early warning of failure, reducing the cost of manual inspection.

In addition to this, the use of lead-free, mercury-free environmentally friendly material design, in line with international green port certification requirements.

FAQ: About ATEX explosion proof light 60w common difficulties

Q1:What is the difference between ATEX certification and IECEx certification?

A1:ATEX is a mandatory certification of the European Union, applicable to the European market; IECEx is an international common standard, suitable for global port projects. Dual-certification products have wider compatibility.

Q2:Can ATEX explosion proof light 60w withstand the high salt fog environment in the harbour?

A2: Yes. High-quality lamps and lanterns with nano-coating and sealing process, anti-corrosion grade up to WF2, can be used in salt spray, humid environment for more than 10 years.