Explosion-Proof Equipment Requirements for Hazardous Chemical Warehouses

Hazardous chemicals refer to highly toxic substances with corrosive, explosive, combustible, or oxidizing properties that pose significant risks to human health, facilities, and the environment. Due to their unique physical and chemical characteristics, improper handling, leaks, or explosions can release toxic fumes or gases. These substances may also pollute air, water, and soil, causing long-term ecological damage. Pollutants can further enter the human body through the food chain, underscoring the critical importance of proper management.

How Can Enterprises Ensure Safe Management of Hazardous Chemical Warehouses?

Hazardous chemical warehouses must be explosion-proof and fire-resistant. Below are specific requirements for the safety management, standards, and explosion-proof equipment specifications for such facilities.

Safety Standards for Hazardous Chemical Warehouses

- Explosion-Proof Facilities

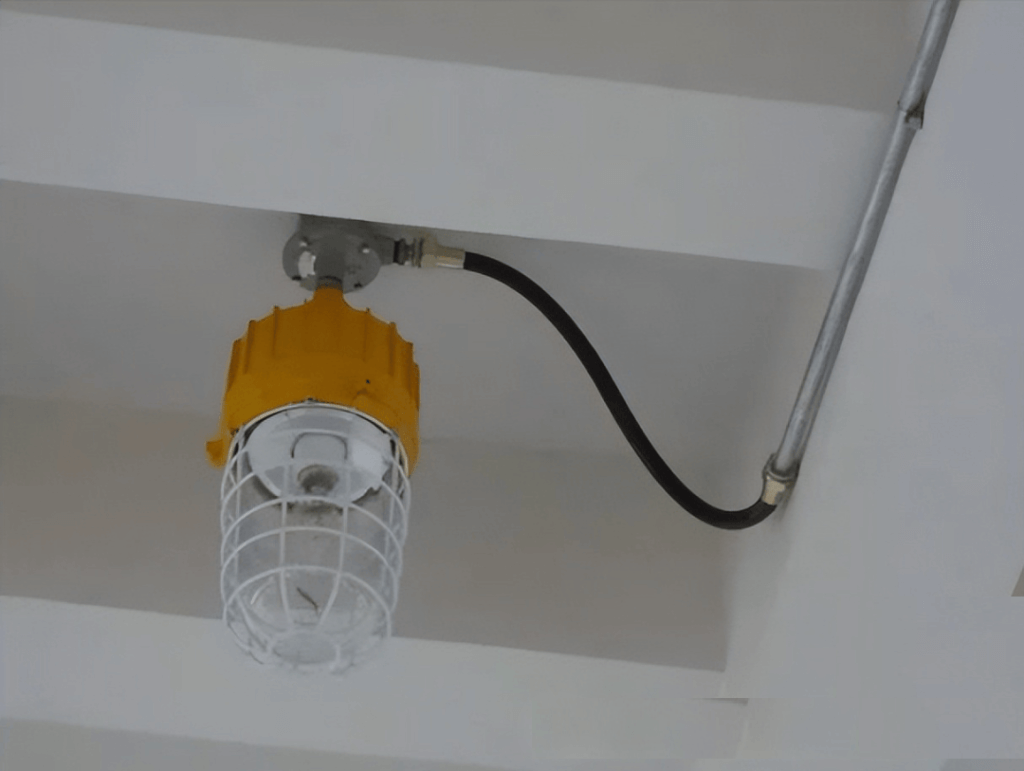

- Electrical equipment, power distribution lines, and handling machinery in warehouses storing flammable or explosive chemicals must be explosion-proof.

- Metal conduits for electrical wiring must be securely fastened with threaded connections. Explosion-proof flexible conduits may be used in areas requiring complex bends.

- Lightning and Static Electricity Protection

- Grounded static discharge devices must be installed at warehouse entrances.

- Ventilation fans, metal shelving, and other conductive equipment must have static-dissipating grounding.

- Lightning protection systems (e.g., rods, strips, nets) must be inspected annually.

- Ventilation Systems

- Flammable liquid and gas warehouses must have emergency explosion-proof ventilation systems.

- Exhaust ducts must be metal and direct emissions to safe outdoor locations.

- Spill Containment Measures

- Liquids (Class A, B, C) require containment barriers, anti-leak pools, and impermeable floors.

- Water-reactive materials must be stored in sealed, dry environments with humidity controls.

- Monitoring and Alarm Systems

- Install gas detectors for combustible/toxic gases at heights aligned with gas density.

- Regularly test alarms through certified agencies and ensure full coverage of hazard zones.

- Firefighting Equipment

- Fire extinguishers, unobstructed hydrants, sprinklers, and smoke vents are mandatory.

- Fire suppression agents must match stored chemicals:

- Flammable/oxidizing gases: Dry powder, sand.

- Flammable liquids: Foam, dry powder, CO₂ (water-soluble liquids require alcohol-resistant foam).

- Flammable solids: Foam, dry powder, sand, CO₂, or water mist.

- Self-igniting substances: Water, dry powder, sand, CO₂.

- Water-reactive materials: Dry powder, sand.

- Oxidizers: Dry powder, water, CO₂.

Explosion-Proof Equipment Specifications

1. Explosion Proof Switches

- Standard household switches or distribution boxes are prohibited.

- Safety Standards:

- 6.1.2.1.1: Equipment type, class, group, environmental conditions, and markings must comply with design specifications.

- Standard Reference: Safety Code for Electrical Explosion Protection in Hazardous Locations.

2. Explosion Proof Wiring

- Use galvanized steel conduits with threaded connections (minimum 5 threads engaged).

- PVC or riveted conduits are prohibited due to poor sealing and low strength.

- Flexible Explosion-Proof Conduits:

- Connect explosion-proof equipment or complex bends.

- Features: Metal threaded ends, rubber outer layer, and steel mesh for static dissipation.

- Prohibited alternatives: Plastic or wax-coated tubes.

Safety Standards:

- Standard 1:

- 5.4.3: Conduits must use galvanized steel pipes with lead or phosphate-coated threads.

- Standard Reference: Code for Design of Electrical Installations in Explosive Atmospheres.

- Standard 2:

- 5.3.2: Threaded connections only; welding prohibited.

- 5.3.6: Install flexible conduits at motor inlets, equipment junctions, and building expansion joints.

- Standard Reference: Construction and Acceptance Code for Electrical Installations in Explosive and Fire Hazard Environments.

3. Explosion Proof Junction Boxes

- Used to connect conduits to equipment. Must carry “EX” certification.

- Unused ports must be sealed. Select boxes based on terminal needs (2-way, 3-way, etc.).

Safety Standards:

- 5.2.1/5.2.3.5: Cables in hazardous areas must connect via explosion-proof junction boxes.

- 5.3.8: Seal unused ports with threaded plugs or pressure-sealed caps.

- Standard Reference: Construction and Acceptance Code for Electrical Installations in Explosive and Fire Hazard Environments.

By adhering to these standards, enterprises can mitigate risks, ensure regulatory compliance, and protect personnel, infrastructure, and the environment from catastrophic incidents.