What is Power Factor? LED Lighting Power Factor Key Information

Introductory

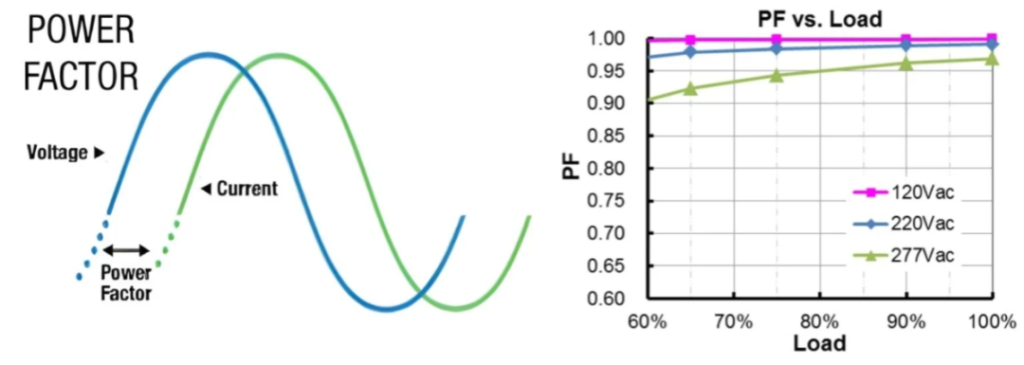

Power factor is the ratio of useful power (i.e., the product of voltage and current) to apparent power, and its value ranges from 0 to 1. Typically, the power factor of LED lighting can reach 0.95, or even 0.97 to 0.99, so it does not receive as much attention in the industry as other parameters (e.g., luminous efficacy, wattage, lenses, etc.).

However, there are still some traditional lamps on the market as well as some LED lamps with low power factor. These fixtures put a greater current load on the grid, requiring the use of thicker copper wires to reduce line overload heating and voltage drop problems, which leads to higher municipal construction costs. Despite the fact that some countries and regions charge extra for reactive power, we believe it is necessary to improve the power factor of power supplies.

Before that, we need to understand what power factor is and its importance. We also need to know under what circumstances LEDs perform better in terms of power factor, as LED luminaires do not always have a high power factor.

What is power factor?

Power factor is the ratio of active power (i.e., the product of voltage and current) to apparent power in an AC circuit. It is an important parameter for measuring the efficiency of electrical equipment and the quality of the power system. Active power is the power in the system that is actually used to do work, while apparent power is the total power of the system, including active power and reactive power (power caused by the phase difference between current and voltage, which usually does not do useful work).

With the power factor formula (power factor = active power / apparent power), we know that the value of the power factor is between 0 and 1, which also includes the power factor of LED lighting.

For a purely resistive load, the power factor is equal to 1, which means that the voltage and current are in phase. This means that all the current is used to do useful work and there is no waste. However, for inductive loads (e.g., motors, transformers, etc.) and capacitive loads (e.g., capacitors, etc.), the current lags or exceeds the voltage, which results in some of the power not being effectively utilized, and the power factor will be lower than 1. A low power factor means that there is a large amount of reactive power in the circuit, which will increase the power supply losses in the line and reduce the utilization of the equipment.

Therefore, improving the power factor helps to reduce the power consumption of the grid and improve the efficiency of the equipment and the quality of power supply. In practice, power factor can be improved through reactive power compensation, optimization of equipment operation mode and other measures.

LED lighting power factor – active and reactive power

Why are we concerned about power factor?

Power factor is of vital importance in power systems. In our opinion, its importance is mainly reflected in the following aspects:

1. Increased energy utilization:

With an uncorrected power factor (i.e., too low a power factor), there is a large amount of reactive power loss in the power system. This useless power is not directly converted into useful mechanical or thermal energy when it flows in the circuit, but it generates extra current in the electrical equipment. This extra current heats up the resistors inside the equipment, thus increasing the energy consumption of the equipment. Conversely, improving the power factor reduces reactive power losses and thus increases energy utilization.

2. Reduce the load on the grid:

Improving the power factor of LED lighting reduces the reactive power in the grid, thereby reducing the load on the grid. This is essential for the stable operation of the power system and helps to avoid problems such as overloading and faults in the grid. On the contrary, a low power factor can lead to excessive current in the grid, which in turn affects the stability of the power system.

3. Affects equipment performance:

A high power factor extends the life of electrical equipment and reduces energy waste. When the power factor is too low, a large amount of useless work is generated in the circuit, leading to severe heating of electrical equipment. Both grid equipment and power-using equipment do not like high-temperature environments. Excessive temperature accelerates the aging of components, leading to performance degradation or even damage. In other words, low power factor not only wastes energy, but also causes damage to equipment.

Low power factor due to different loads

The low power factor is mainly due to the use of inductive and capacitive components. Equipment can be categorized into inductive and capacitive loads depending on the number of inductive and capacitive elements. Equipment with more inductive components are inductive loads, while equipment with more capacitive components are capacitive loads.

Purely resistive loads

In addition to inductive and capacitive loads, there are a number of devices, appliances, and lamps that are purely resistive (i.e., pure ohmic loads). It refers to loads where the circuit contains only resistive components. When energized, the circuit produces only heat and light energy and does not convert electrical energy into other forms of energy. In a purely resistive load, the current and voltage change synchronously, i.e., they are in phase. This means that there is no phase difference between the current and the voltage and therefore the power factor is equal to 1.

A typical example of a purely resistive load is an incandescent lamp. When an incandescent lamp is lit, electrical energy is converted primarily into heat and light, where heat is generated due to the passage of current through a resistance wire. Since incandescent lamps are purely resistive loads, their power factor is close to 1, which means that incandescent lamps are able to efficiently utilize electrical energy and convert it into light/heat without generating a lot of reactive power. Of course, this does not mean that incandescent lamps have the highest light efficiency.

inductive load

Inductive loads are loads that contain a large number of inductive components in the circuit and are one of the main causes of low power factor in equipment. Inductive loads include motors, transformers, and inductors, etc., which generate a magnetic field during operation that causes the current to lag behind the voltage. This lag causes a phase difference between the current and voltage, which reduces the power factor. A typical example of an inductive load is HID lamps, whose electromagnetic ballasts are inherently inductive, resulting in a power factor that is usually around 0.7 or even below 0.5. LED lamps also fall into this category, although LED lighting can have a power factor of 0.97.

Inductive and capacitive loads

capacitive load

Capacitive loads are loads with a large number of capacitive elements in the circuit. Unlike inductive loads, capacitive loads (such as capacitors) cause the current to overrun the voltage, thus improving the power factor. However, if the capacitive reactance is too large, so that it is greater than the inductive reactance, then the current will overshoot the voltage by a large phase angle, which again results in a drop in power factor. Often, capacitors are added to devices such as LED controllers to compensate for reactive power and improve the power factor of LED lighting.

Fundamentals of Power Factor

In the previous two sections, we learned that the presence of inductive and capacitive components in equipment can lead to a reduction in the power factor of the equipment, so what are the specific reasons? Below we explain the basic concepts in a more generalized way.

When inductive loads (i.e., components that generate magnetic fields, such as motors, transformers, and inductors) are present in a device, the current passing through these devices generates a magnetic field to store energy. If we imagine the magnetic field as a bucket and the current as water, when we turn on the faucet, the water begins to flow into the bucket, but the bucket doesn’t fill up immediately.

This is because it takes a while for water to flow and fill a bucket. Similarly, when a current flows through an inductive load, it creates a magnetic field inside the load, but this field takes time to build up. This current due to the establishment of the magnetic field is called “inductive reactive current”.

This current is not actually converted into useful energy for the load, but is stored in the magnetic field. There is a phase difference between this current and the voltage, i.e., the voltage has begun to change, but the current has not yet reached the magnitude of the voltage change.

In inductive loads, these components (e.g., electric motors) may lead to an increase in energy consumption on the grid, even though the motor itself does not consume that much energy. This is because inductive loads consume reactive power in addition to active power. The reactive power is not used directly to do work, but to maintain the magnetic field inside the device.

Due to the presence of inductive loads, current circulates in the system, causing the total energy (apparent power) in the system to increase. Since inductive loads consume reactive power, the grid needs to supply more current to meet the needs of the equipment. This leads to an increase in the energy consumption of the grid, even though the motor itself does not consume that much energy.

Therefore, the impact of reactive power needs to be considered when designing and operating inductive loads to improve equipment efficiency and reduce grid energy consumption.

Factors affecting power factor in LED lighting

In the previous two sections, we described what power factor is, why it is important and how power factor differences affect the grid. In this section, we explain what factors affect the power factor of LED luminaires.

Use of lower quality power supplies

As a major component of the luminaire, the LED power supply has a significant impact on the power factor of the LED lamp. This is due to the fact that there are more inductive components in the power supply than any other part of the fixture. However, LED controllers from different power supply manufacturers vary greatly in their power factor performance.

For example, the power factor of Infinity EUM series power supplies can reach 0.97 or even higher, while the power factor of MOSO MXG series power supplies can only reach 0.95. Different series of LED controllers from the same manufacturer also vary greatly in terms of their power factor performance. For example, the D4i power supply from Igor EBS-080S105BT2 can reach a PF of 0.98.

Poorly configured power supply

The power factor of the same power supply varies greatly in different fixture configurations. Here the fixture configuration mainly depends on the degree of matching between the fixture load and the LED controller. From the table below we can see that the smaller the fixture load, the worse the PF value. Taking EUM-075S105DG as an example, when the luminaire load is 72W (total luminaire power is 80W), the PF can reach 0.97. If the luminaire load is reduced to 60W, the PF will be reduced to 0.96, and if it continues to be reduced to 50W, the PF will be reduced to 0.95 or even lower. The right thing to do at this point is to use the EUM-050 power supply to control the corresponding LED module to get a better PF value.

Power factor of LED controller

Use of dimming function

The dimming function in LED luminaires is widely used. Although dimming can save energy, we also need to pay attention to its effect on power factor (PF). In roadway lighting, LED streetlights will reduce power to minimize overlighting when traffic decreases after midnight. Another example is in warehouse lighting, where LED industrial lights adjust their output based on space occupancy (occupied or unoccupied) to reduce unnecessary lighting.

Usually, when the lighting demand is low, the LED fixtures will reduce the power by changing the output of the LED controller to save energy, i.e. reducing the output power of the LED controller. From the second point we can understand that in this case, the power factor of LED lamps may be reduced. It is recommended that in this case, the power reduction should not exceed 50%. If the power reduction is more than 50%, a balance between energy saving and power factor value is required.

Summarize

Power factor is an important parameter for limiting reactive power in electrical equipment, it is an indicator of the comparison between real, apparent and reactive power in the equipment. LED controllers perform better in terms of power factor due to the use of an internal power factor corrector (PFC).

Different LED controller suppliers have different capabilities in this area and LED luminaire manufacturers are advised to investigate them. At the same time, we should try to avoid low power factor due to unreasonable fixture configuration (too low load).

In addition, the power factor values of LED luminaires under full load and dimming systems vary considerably. However, we believe that a lower LED lighting power factor is not an issue during dimming relative to the input current consumed.