ATEX explosion proof led light fixture in the ship lighting fundamental applications and advantages of analysis

Introduction

The marine industry has very high requirements for the safety and reliability of lighting equipment, especially in flammable and explosive environments.

ATEX explosion proof led light fixture have become the ideal choice for marine lighting due to their strict explosion-proof certification and high performance features.

This article discusses ATEX explosion proof led light fixture in the marine field of core application scenarios, technical advantages and selection proposition, to help industry users to improve safety and energy efficiency.

First, why the marine industry need ATEX explosion proof led light fixture?

Ships often exist in the environment of oil and gas, dust and other flammable substances, traditional lighting equipment is easy to trigger the risk of explosion.

ATEX explosion proof led light fixture are approved by the European Union ATEX directive, using sealed structure, impact-resistant materials and anti-arc design, effectively isolating sparks and high temperature, to protect the hazardous areas [such as the cabin, the cargo hold] operational safety.

Its low energy consumption, long life characteristics can also reduce the cost of ship maintenance, in line with the requirements of maritime environmental protection.

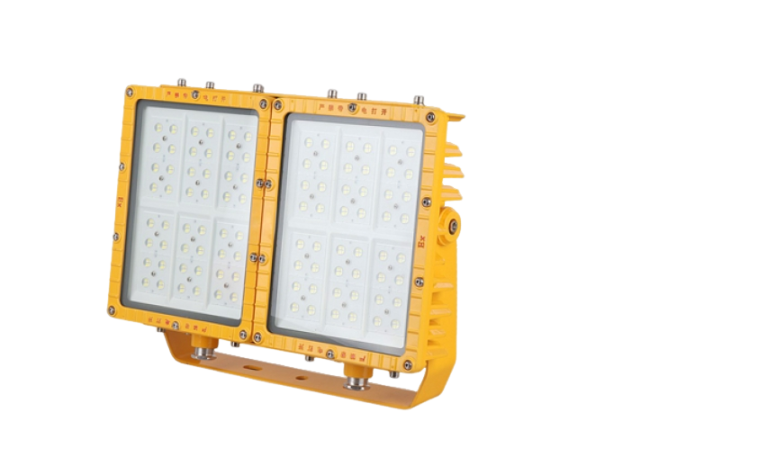

Second, Amasly ATEX explosion proof led light fixture core technology advantages

1. Excellent explosion-proof performance approved explosion-proof [Ex d] or increased safety [Ex e] design, ATEX explosion proof led lamp fixture can be in Zone 1/Zone 2 explosive gas environment stable operation, protection level up to IP66/IP67, against humidity, salt spray corrosion. 2.

2. energy efficient and long life using high luminous efficiency LED chip, energy consumption is reduced by more than 60% compared with traditional lamps and lanterns, the average life expectancy of more than 50,000 hours, to reduce the burden of frequent replacement of operation and maintenance.

3. Intelligent dimming and vibration-resistant design to help stepless dimming, remote control, adapting to the needs of different working conditions on board; anti-vibration structure to ensure stable lighting in bumpy seas.

Third. ATEX explosion proof led light fixture in the ship typical application scenarios

1. Cabin and pump room high humidity, oil and gas mixed environment needs explosion-proof and anti-corrosion double protection, ATEX lamps can supply uniform lighting and avoid the risk of sparks. 2.

2. Cargo compartment and deck area explosion-proof LED light impact shell to adapt to the cargo handling collision, wide temperature range design [-40 ℃ ~ 60 ℃] to ensure that the performance of extreme cold or high temperature environment stability.

3. corridor and escape channel in case of emergency, low-power emergency lighting module can work continuously for more than 2 hours to enhance the safety of crew evacuation.

Fourth, how to choose the right ship ATEX explosion proof led light fixture?

1. Certification compliance: confirm that the product complies with the ATEX 2014/34/EU Directive and IECEx international standards. 2.

2. environmental suitability: according to the installation area [Zone classification] to choose the corresponding protection level and material [such as 316 stainless steel]. 3. energy efficiency and light parameters: energy efficiency and light parameters.

3. Energy efficiency and light parameters: Priority should be given to luminous efficacy > 120lm/W and colour temperature 4000K-5000K to balance visibility and comfort.

Fifth. Future momentum: intelligent and sustainable

Accompanied by the shipping industry to the green development, integrated sensors and the Internet of Things intelligent ATEX explosion proof led lamp fixture will become mainstream.

For example, the approval of the light sensor automatically adjusts the brightness, or approval of the data back to the implementation of fault warning, to further reduce energy consumption and artificial inspection costs.

FAQ: ATEX explosion proof led light fixture on common problems

Q1:What is the difference between ATEX certification and ordinary explosion-proof certification?

A1: ATEX is the EU mandatory certification guidelines, requiring product approval of explosive atmospheres, rigorous testing, covering the design, production and labelling of the entire process, more comprehensive than ordinary explosion-proof certification.

Q2: Is ATEX explosion proof led lamp fixture suitable for high salt spray environment at sea?

A2: Yes. High-quality ATEX lamps and lanterns with vacuum coating or nano-coating process, can resist salt spray corrosion, suitable for ships and offshore platforms for long-term use.

Q3:How to judge whether the explosion-proof level of the luminaire matches the needs of the ship?

A3: According to the International Electrotechnical Commission [IEC] Zone guidelines for selection, for example, Zone 1 [gas environment] need to be Ex d IIB T4 or above.

Q4:What is the maintenance cycle of ATEX explosion proof led lamp fixture?

A4:Because of its long-life design, it is often only necessary to check the seals and circuit connections every year, and can be used for 5-8 years without any problems.