Atex explosion proof light in the oil and gas industry in the core role of safety lighting and innovative applications: to build an intrinsically safe production environment

First, why the oil and gas industry must choose explosion-proof lights? From accident data to safety needs

Oil and gas industry is a typical high-risk operation scene, crude oil, natural gas, refinery products are flammable and explosive substances. According to statistics, the global oil and gas industry accidents, about 23% of the explosion caused by electrical equipment sparks or high temperature.

Ordinary lighting fixtures in the oil and gas environment probably due to electric arcs, surface high temperature or mechanical impact ignition of combustible gases, and Atex explosion proof light approved explosion-proof structural design, temperature control technology, sealing and protection process, to fundamentally eliminate the risk of ignition source.

Let’s say, a multinational oil group in the refining and chemical plant area upgraded to LED explosion-proof lights, three years after the electrical-related accident rate fell 87%, to verify the explosion-proof lights in the intrinsic safety of irreplaceable.

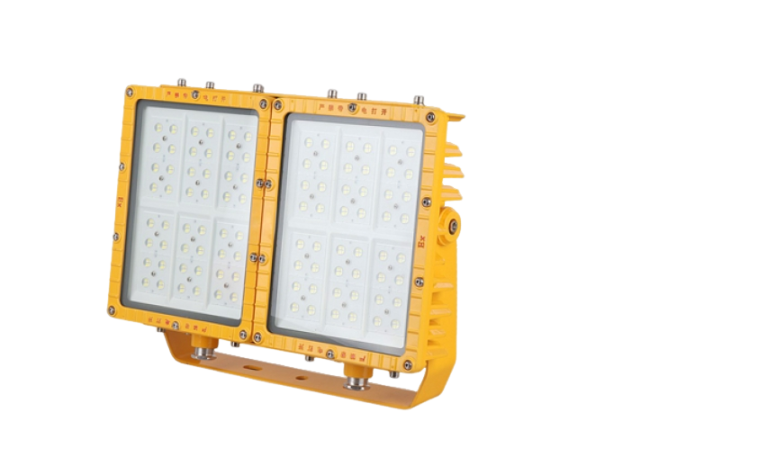

First. Atex explosion proof light core protection mechanism

Explosion-proof [Ex d] design: high-strength aluminum alloy shell can withstand the internal explosion pressure, to prevent flame leakage;

Temperature suppression technology: approved heat dissipation improvement and low-power LED light source, the surface temperature will be controlled below the gas ignition point [often ≤ 80 ℃];

Multi-environmental adaptability: IP66/67 protection against corrosive gases, high humidity and dust in oil and gas places.

Second, explosion-proof lights in the oil and gas industry technology breakthroughs: from the cornerstone lighting to the intelligent Internet of things

1. LED technology revolution: energy efficiency and safety double enhancement

Traditional metal halide Atex explosion proof light and lanterns with high energy consumption, short life [about 15,000 hours], while the LED Atex explosion proof light luminous efficacy of up to 120-150 lm / W, life expectancy extended to 50,000 hours, the overall energy consumption by more than 50%. For example, an offshore oil platform using LED explosion-proof lights, annual power savings of more than 2.1 million degrees, maintenance costs reduced by 40%.

2. Intelligent monitoring system integration

A new generation of Atex explosion proof light equipped with Internet of Things modules, real-time monitoring of lamps and lanterns temperature, power consumption and fault status, and approved 4G / WIFI transmission to the central control platform. After deploying the intelligent explosion-proof light system in a Middle East oil refinery, the unplanned downtime has been reduced by 65%, and the fault response efficiency has been increased by 80%.

3. Emergency function enhancement

Explosion-proof emergency lights are equipped with lithium iron phosphate batteries, which can be automatically switched when the main power supply is interrupted, and can provide continuous power supply for ≥90 minutes, which meets the EN 60598-2-22 standard, and is suitable for high-risk scenarios such as oil tank areas and wellhead operations.

Third, the oil and gas industry Atex explosion proof lamp selection of five fundamental elements

1. Explosive partition matching Zone 0 [continuous presence of explosive gases]: Ex ia level Atex explosion proof light; Zone 1 [probably occasional]: recommended Ex d/Ex e combination; Zone 2 [short-time presence]: Ex nR Atex explosion proof lamp.

2. Optical parameters customized storage tank area: 120 ° wide-angle Atex explosion proof light, illuminance ≥ 300 lx; pipe corridor access: linear Atex explosion proof light, uniformity > 0.7; loading and unloading terminals: 200W high-power floodlights, vertical illuminance > 150 lx.

3. Enhanced environmental adaptability marine platform: choose salt spray corrosion-resistant 316L stainless steel; desert oilfield: anti-UV coating with -50 ℃ ~ +80 ℃ wide temperature range design 68.

4. Full life cycle cost improvement

LED explosion-proof lights: 10 years total cost of ¥ 79 million, maintenance frequency of 5 years / time

Traditional Atex explosion proof light: 10 years total cost of ¥ 1.28 million, maintenance frequency of 1 year / times

5. Certification and compliance non-approved IECEx, ATEX certification, and in line with API 500/505 oil and gas industry-specific guidelines.

Fourth, the global benchmarking case: Atex explosion proof lamp practice results analysis

1. a refining base in Northern Europe deployed 572 sets of Class IIB Atex explosion proof light, integrated DALI dimming system, annual power savings of 2.1 million degrees, and successfully resisted a number of gas leakage events.

2. Middle East petrochemical warehousing project selected Ex tD dust Atex explosion proof light, PM10 concentration > 800 μg/m³ environment for three years of continuous operation, the lamps and lanterns to reduce the rate of accumulation of dust 73%.

3. China’s Bohai Sea offshore platform using photovoltaic explosion-proof lighting system, combined with MPPT controller, the implementation of off-grid environment zero-carbon emission lighting, operation and maintenance costs reduced by 60%.

Fifth, explosion-proof lights intelligent maintenance and sustainable development strategies

1. preventive maintenance system quarterly inspection of sealing, cleaning surface oil; annual testing of emergency battery capacity and switching function.

2. Employee safety training approved VR simulation exercises to enhance the operators of Atex explosion proof light fault identification and emergency response skills, to reduce the risk of human error.

3. circular economy model LED Atex explosion proof lamp 90% of the material can be recycled, and no mercury pollution, in line with the oil and gas industry ESG intentions.

Sixth, the future technology momentum: explosion-proof lights intelligent and green

1. digital twin technology applications approved 3D modeling simulation of different gas concentrations under the Atex explosion proof light performance, improved lighting scheme design.

2. new energy integration of wind and storage integrated explosion-proof lighting system has been piloted in remote oil fields, reducing reliance on diesel generators.

3. material innovation graphene heat dissipation technology to reduce the weight of the lamps and lanterns by 20%, light efficiency increased by 15%; transparent ceramic lampshade impact resistance is 5 times higher than glass.

Conclusion: Atex explosion proof light – the cornerstone of safety lighting in the oil and gas industry

In the oil and gas industry safety production system, Atex explosion proof lamp are not only lighting tools, but also risk prevention and control of core components. Choose to approve the IECEx certified Atex explosion proof light suppliers, laying a regular testing system [advocating the implementation of IP protection test every 6 months], you can build an intrinsically safe lighting environment.

Accompanied by the integration of intelligent and green technology, explosion-proof lights will continue to promote the oil and gas industry to high-efficiency, low-carbon, zero-accident intention to move forward.