Chemical plant explosion-proof requirements and part of the required explosion-proof products

Explosion protection requirements for chemical plants include the following:

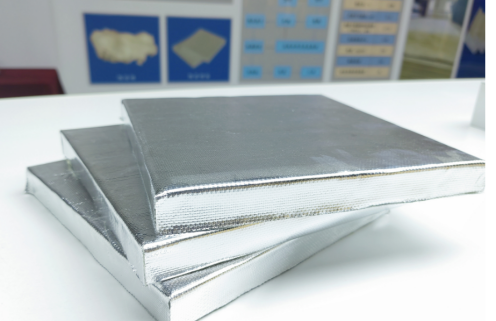

Requirements for equipment and facilities: Electrical equipment must comply with national electrical explosion-proof standards, and the configuration must match the regional hazard level and be regularly inspected and maintained. Lightning protection and electrostatic conductivity facilities need to be installed, configured and tested annually in accordance with the regulations, in order to prevent static electricity buildup from causing fire or explosion. Production equipment and devices must be equipped with safety facilities in accordance with national regulations, and the equipment and pipelines should be made of fireproof materials and comply with relevant national fire prevention standards.

Safe operation norms:

The requirements for the management of hazardous chemicals are strict, and smoking and the use of sparks or static electricity, such as pyrotechnics, are strictly prohibited in areas where hazardous chemicals are stored, produced or used. Warehousing sites should be clearly marked with the name, characteristics, fire prevention measures and fire extinguishing methods, and equipped with the necessary fire-fighting equipment. Non-routine operations, such as opening and stopping of installations, need to be listed and managed, risk identification carried out, and safe operating procedures and emergency disposal measures formulated.

Emergency management measures:

Enterprises should formulate emergency plans for fires and explosions, including procedures for alarming, evacuating and extinguishing fires, and conduct regular drills. Safety alarm systems and safety surveillance systems should be set up at workplaces with high fire risks, toxic and hazardous workplaces, and regular toxic gas monitoring should be carried out. Employees at work sites should be given health checks and regular training to enhance their safety awareness and operational skills.

Explosion-proof classification criteria are based on the type of equipment used, the temperature group of the explosive gas mixture and the explosion-proof type of electrical equipment. The explosion-proof marking usually includes information on the type of equipment, the explosiveness of the gas or vapor, and the temperature group.

The main types of explosion-proof equipment needed in chemical plants include the following:

Chemical explosion proof positive pressure cabinet:

This kind of equipment effectively prevents external explosive mixtures from entering the cabinet by continuously maintaining a positive pressure state higher than the external ambient pressure inside the cabinet, so as to achieve the purpose of explosion-proof. It is usually made of stainless steel and other high-strength, corrosion-resistant materials, and through precision machining and sealing technology to ensure that all interfaces, gaps to achieve a good sealing effect. Chemical explosion-proof positive pressure cabinets are widely used in all aspects of the chemical industry, including the production, storage and handling of flammable and explosive chemicals, providing safety for electrical equipment and control systems.

Lighting:

Such as explosion-proof lamps and explosion-proof ballast lamps, these devices are used in chemical plants to provide lighting with explosion-proof features to ensure safe use in hazardous environments.

Air conditioning and ventilation:

Explosion-proof air conditioners and explosion-proof ventilators provide the necessary ventilation and conditioning in chemical plants without causing explosions.

Distribution boxes and control cabinets:

Explosion-proof switchboards and control cabinets are used to control and distribute power to ensure safe operation in hazardous environments.

Various switches, buttons, sensors, combustible gas detectors, surveillance cameras, etc:

These devices are used in chemical plants to control and monitor production processes and are also explosion-proof to ensure proper functioning in hazardous environments.

Motors and fans:

Explosion-proof motors and fans are used to drive a wide range of mechanical equipment to ensure safe operation in hazardous environments.